Click Muse 10 to display the cruise so far in a new tab.

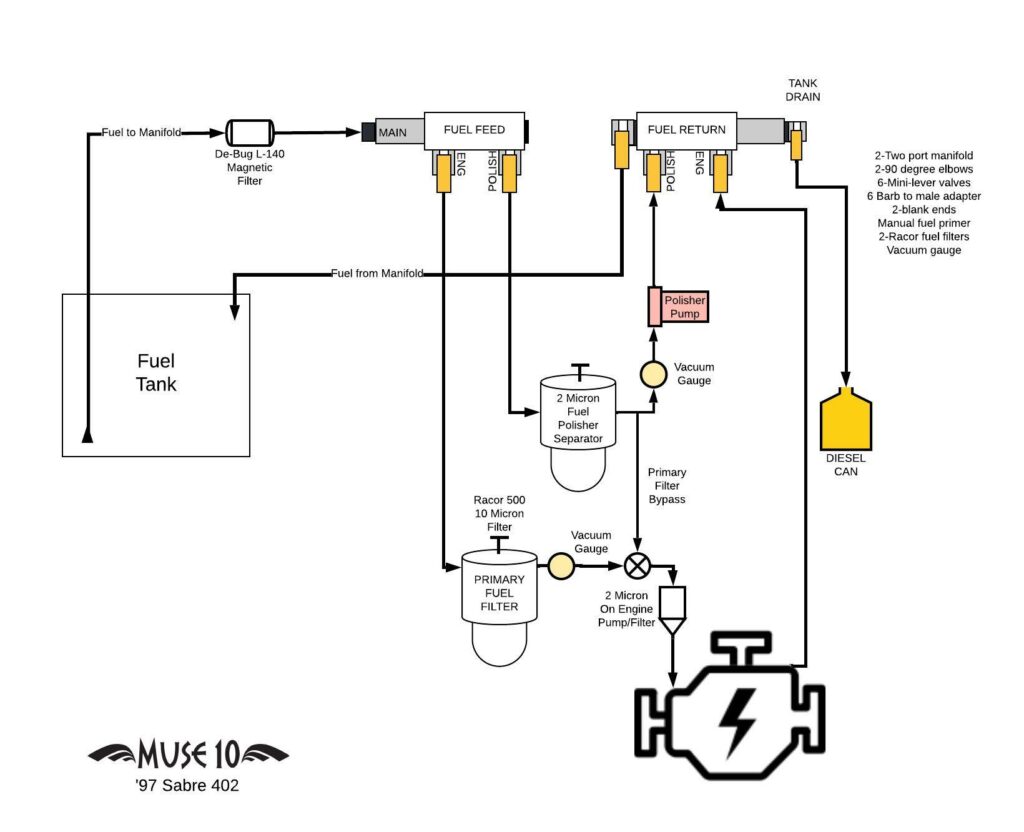

Adding a Fuel Polishing System

So, I’ve re-learned a valuable lesson about clean fuel. I’ve just designed a fuel polishing system for the boat and now have most of the parts.

I’m heading to Oriental in a couple of weeks to start the cleaning and I’ll share my findings.

This is my pre-install design.

Consequential Damage – Another Lesson

Consequential damage: an insurance term, is an incident that is the result of a preceding one. Often it’s more extreme than the original insult. For example, a leaky through-hull leads to the boat sinking.

On June 1st, 2022 we left the safety of our slip on Hilton Head Island heading for the coast of Maine. We planned a summer of cruising in the waters we had sailed in years past, stopping along the way North to visit with friends.

The first issue came the second night at sea. We were running the engine at about 0300 to top off the batteries while offshore around Wrightsville Beach, NC. We had run the engine for about 20 minutes when it began to sputter and then died. I went to the engine area and checked the vacuum gauge on the fuel line to see if we had a fuel restriction issue. We did. We were bouncing a bit and we threw up some sediment – the stuff you don’t see too much when sailing in the bays. We had reasonably new fuel, I regularly add an enzymatic biocide and lubricity enhancer to my fuel. I have seen this problem on other offshore passages. I checked the Racor separator/filter for water and slime. It wasn’t bad but I noticed the bowl wasn’t full of fuel. I manually re-primed the engine and she started back up. We ran the engine again later and all went well.

We stopped in Beaufort, NC with no trouble till we were leaving the slip and I couldn’t get full power. We made it to mid-channel past the marina and I dropped the hook to work on it again.

Of course, it was a Saturday and we could most likely not find a mechanic till Monday. I re-primed and restarted the engine. We continued on to Oriental, NC. I replaced the Racor and spin-on/on engine filters. When I restarted the vacuum gauge was about 3-5 and held there for some testing. I thought I had found the issue and it was resolved. On Sunday morning we had a stiff wind from on the nose as we headed N through Pamlico Sound on a long fetch. After another bout of pounding in short choppy 4’ waves, the engine died again. It’s a sailboat so we turned the boat 180 and started sailing back to Oriental. We made it back into the Oriental breakwater and I dropped the hook. After inspection, it was the same problem. I decided the problem was somewhere between the fuel tank and the Racor, so I used the spare fuel line hose I had on board and bypassed it using only the 2micron spin-on filter to get us to the “Free dock” where I could do a closer inspection.

I restarted the engine. It faithfully restarted with the new fuel path. I then headed into the town dock with lots of spurious wind in the harbor. I tried to dock but was blown off and went around for a second try. Karen (my wife and sailing partner) was standing outside the lifelines holding on to a shroud and mid-ship line. When the boat came to a stop alongside the dock (lee side) she would step back onto the dock and tie us to a piling or cleat.

I pulled the boat up to the dock very slowly and she stepped off the boat extending a straight leg to the dock to tie her up at the beam initially to secure her close to the dock. We have done this maneuver hundreds of times during our sailing career. We each have about 40,000 offshore miles.

This time was different. As soon as she landed she screamed out in pain quickly laying down on the dock. She tied the boat off to a cleat hidden on the back of the piling. These were very short pilings. They just went to about level with the toe rail.

The rest of the crew came to her aid quickly as she writhed in pain coming from her knee. As she was about to pass out from the pain she said “I have dislocated my knee”. We called 911 and they quickly took her to the New Bern, NC hospital. In the ER we found out she had broken the “Tibial Plateau”, a classic spiral fracture that would need to be surgically reduced with metal screws and a plate. After 10 days and two surgeries, she was on the mend and still is.

There is a myriad of lessons here to be learned.

- When is an issue fixed?

- Should I have called for help to dock the boat?

- Should I have anchored out and worked on the engine more?

- Should we have dis-embarked the boat in a different way?

- Should we have put a large loop out and thrown it over the pilings – then snugged it up?

The pilings were just at toe rail height. The line could have slipped off the top. We were not making much way and we would have been blown into the steel fishing boat some 10’ on our lee. - The corner piling was higher than the rest. I could have put down a “marriage saver”. It’s a loop between the stern cleat and the beam cleat that you throw over the piling. It slows the boat and should stop it before the end of the dock. If you stay in forward the boat will turn toward the dock while you disembark. We use it with students when teaching ASA classes.

I’ve replayed this incident many times in my mind.

The boat was going dead slow – less than .5 kt. We were moving just enough to slide alongside the dock and not get blown off. This was a procedure we have executed many times without incident. The engine was not giving us an issue at the time. I could have set the anchor and worked on the engine in the harbor.

I could have waited to head North until the wind changed and lowered the chop.

I could have asked her to park the boat and I would step off by switching positions.

In my current analysis, I think it’s probably a combination of things.

Karen’s bones are getting a little more brittle with age. She had her bone density checked but didn’t have the results at the time and we’ve since found out that she has some Osteopenia (low-grade Osteoporosis). Combined with twisting the foot as she stepped backward on the dock and about a 30” drop from the toe-rail to the dock, we come up with the consequential and significant damage to my dear wife and partner.

I realize that sharing this info might bring on some scrutiny that might not seem welcome. I have always tried to learn and grow from my mistakes. So, any constructive input is welcome.

Here is what I’m doing now:

- Taking care of my wife.

- Preparing to return to our boat in NC

- Preparing to polish my fuel with a new system

Temporary at first then a permanent fixture - Upgrading my fuel filtering system

- Buying an inflatable step fender to deploy in the future

To lessen the distance for short legs to the dock - I disassembled the Racor and inspected it. The 10micron removable filter was not really dirty/slimy in a way I would have expected. I did find some hard crusty green particles under the float ball in the separation turbine during the inspection.

- Providing Karen additional training in docking so I can share in the tie-up fun

- I ordered a “Plastimo 2 Step Fender Ladder” to assist in boarding and disembarkation.

I often quote one of my father’s golf sayings – in sailing never more true than here.

“You drive for show and putt for dough”. Many issues in handling boats are won or lost in the close game.

Karen On the Mend

On Monday we saw the Orthopaedic Trauma Surgeon in Charleston we selected for Karens Tibia repair. He arranged surgery for Wednesday, June 15.

We arrived at the MUSC in Charleston at about 5:15 in the morning. By 10:30 am I was being ushered into postop to visit with Karen. She overnighted in the hospital and brought her home on Thursday with an ample array of screws and a new plate in her Tibia. She will recuperate at home till about the 23rd and we go to KY for my mom’s 90th birthday. Oh, did I forget that two days after Karen’s incident, mom fell and broke her hip and maxilla with multiple contusions on her face? It’s been a big week. She is now recovering from hip surgery at the Willows in Lexington, KY.

A Pivotal Incident on the Way to Bellhaven, NC

On Sunday the 5th of June we pulled anchor, stored the dinghy, and motored out of Oriental. The wind was out of the N at 20-25 kts. On the way in under bouncy conditions, we had some issues with fuel starvation on our diesel when running it to charge batteries/cool down the engine-driven freezer. I was able to get the starvation issue resolved (I thought). That’s what the vacuum gauge said anyway.

We were motoring into the wind on a long fetch and the engine as we rounded into the ICW again about 12 Mi N of Oriental. The engine died and I decided we should sail back and go into Oriental for a professional check.

I contacted TowBoat US and they said they would be standing by to intercept us at the harbor entrance as we sailed back into Oriental. A couple of hours later we got close to the harbor and called for the tow and the response was that they were on another call. We will have to wait.

So we set up the anchor and sailed into the harbor, rounding up just out of the standing chop. The boat settled at anchor and I went down to the engine compartment and made another assessment of the situation. It appeared there was an issue in the Racor module. The 20micron filter was pretty clean with a few bits. I had about 10′ of fuel line so I just bypassed the Racor and restarted the engine. It took right off and the vacuum gauge stayed well within tolerance.

We pulled anchor and headed into the Oriental Town Free dock to tie up and look for a mechanic.

As we approached the dock, the wind caught us dragging the bow away from the dock. We went around again and approached slowly. Karen stepped outside the lifelines holding a beam-cleated dockline in one hand. The boat was moving slowly if at all. As she stepped back her leg twisted and she fell on the dock. She managed to cleat off the line and then about passed out.

Long story short….. She broke her Tibial Plateau at that moment.

We got her to the hospital via ambulance. At the time she/we thought she had dislocated her knee. Once in the ER and after an X-Ray, we saw what the damage was.

She had a temporary surgery on Monday to straighten the leg and stabilize it till we could get her to a trauma Orthopaedic surgeon.

She was discharged from the hospital on Thursday and we stayed in a local hotel “The Oriental Inn and Marina” till Saturday. Linda Griffin picked us up and brought us home to HHI.

Stu and Howard have been a great help in this ordeal. Howard lent his truck to me for the week. Stu helped me dock the boat in a short-term slip nearby and is checking on the boat while we recover. We are blessed to have such wonderful friends.

Thank you all!

Now we recover at home till Wednesday when Karen will have her Tibia repaired and we can start the 8 week recovery period.

A Warm Welcome in Oriental, NC

On Saturday, June 04 we left Beaufort and motored to Oriental, NC. On Saturday morning the wind turned and came from the North. It was blowing 20+ kts. It made an interesting exercise getting out of the slip. We made the trip from Beaufort to Oriental on the ICW in about 4 hrs.

The reason(s) we wanted to visit Oriental is that we have multiple friends that live in the village. Howard and his wife Ros Cheetham sailed with us in the WorldARC. Another friend, Stu Robinson with Arrow his cat was a slip mate for many years while we were in Green Turtle Bay.

We anchored in the Oriental harbor, launched the dinghy and all four of us headed into town. We had a lovely reunion.

Oriental is a village of about 500 folks it sits on the banks of the Neuse River. Not a river in the inland sense where Oriental is located. It’s part of an inland sea making up the Albermarle-Pimlico Estuary. It’s about 3000 square miles of open water.

Good Passage to Beaufort, NC

We left our boats home in Windmill Harbour in Hilton Head on Wednesday, June 01 about 2:30 pm. We entered the Atlantic Ocean at about 5:30 into a 2-3 ft sea running with a 15 kt wind from the SE. Our sails were set on the quarter and we started our 300 mi passage to Beaufort, NC.

We had a good sail with pretty consistent winds for about 30 hrs. The wind began to clock a bit and we sailed wing on wing with preventer into Beaufort. We arrived in Beaufort at about 1:30 pm on Friday, June 03.

We spent the night at Homer Smith docks exploring the town and having a nice meal at the Rhumbar on Front Street.

Almost time to leave, the packing begins

The plan is for a ~ 9:00 am departure tomorrow, June 01. Tom and Fran D’Andrea have joined us for the first leg to Georgetown, Md.

Have you noticed how much the bilge is running?

We got back to the dock on our Sat/Sunday shakedown cruise to find the bilge running more than usual.

We start checking and the freshwater pump won’t keep pressure and there is water in the bilge. So we start the diagnosis by emptying the cockpit lazarette. It’s big and holds a lot of stuff.

We finally found the issue after about 30 minutes of looking for the break. One of the nylon/vinyl hose junctions popped loose and was spraying water all over the water heater compartment.

Now that’s fixed and we can head to the next issue. Making chocolate chip cookies.

Memorial Weekend Shakedown Cruise

After all the abuse/love we have been heaping on the boat we thought we needed a shakedown system run on the boat. Today is a great opportunity for a pre-voyage test. All is good so far.

Working on New Bimini

Brian from Halifax Marine Canvas is installing a new bimini today.It’s much larger than the previous one.

We have added a second 170W solar panel to bring us to a total of 510watts at peak.

We are adding a see-through bridge piece and curtains.

The finished work is due on Monday.